Product description and specifications: Silicon Carbide XBPM sensors are composed by diodes in 2x2-array configurations, with gaps of 6 μm, large active areas and a central region with defined high transparencies. XBPM are typically supplied together with 3x4 cm2 aluminum-core circuit boards for easy connection. Mounted sensors are air- as well as UHV- (10-8 mbar) compatible. Mounted sensors come also with metal covers to avoid damage to the sensor surface during handling and installation. All sensors can be operated at zero bias with >80% Charge Collection efficiency (CCE).

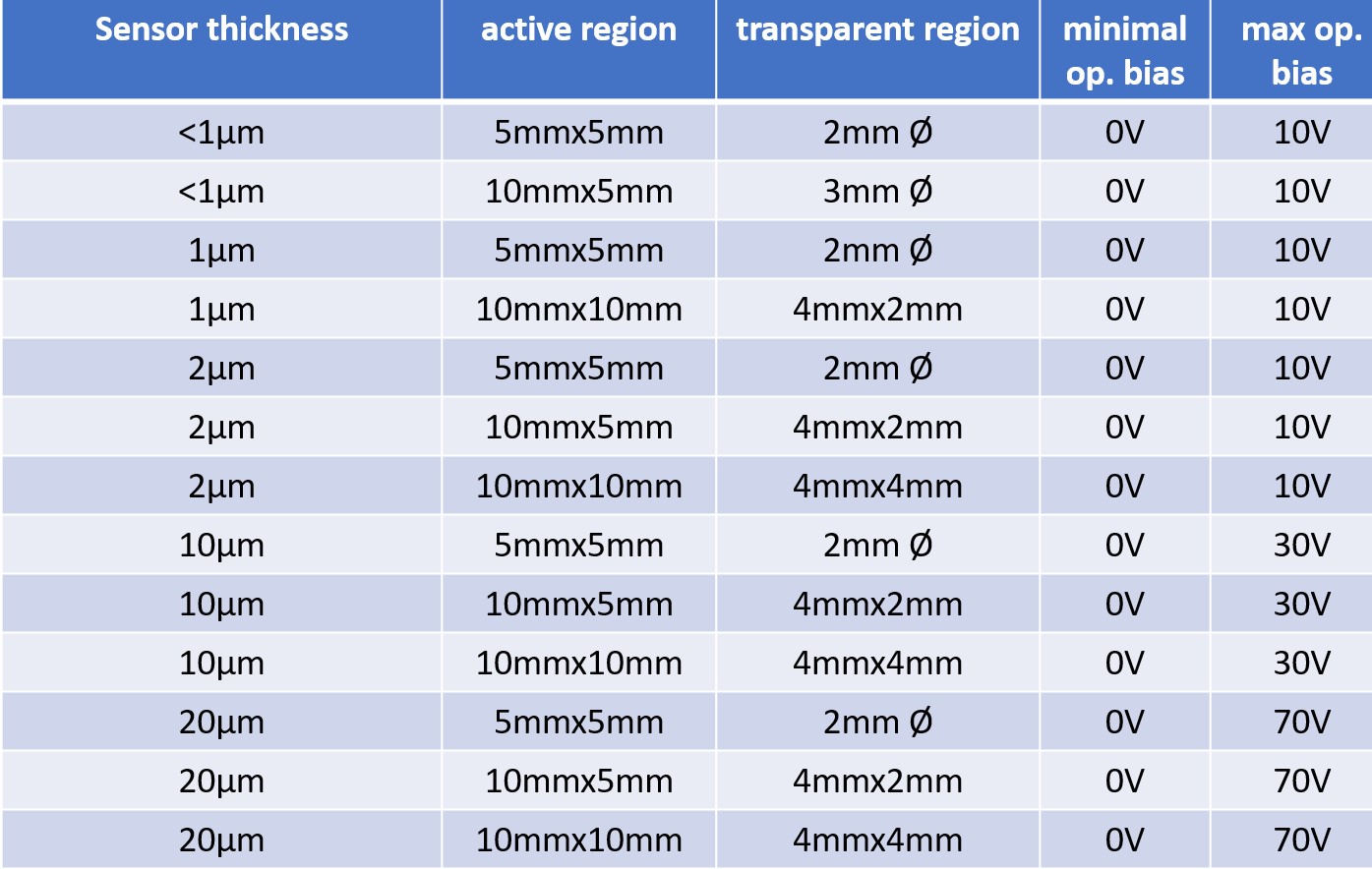

Tab.1 Price tag for different XBPM sensors, other geometries available upon request

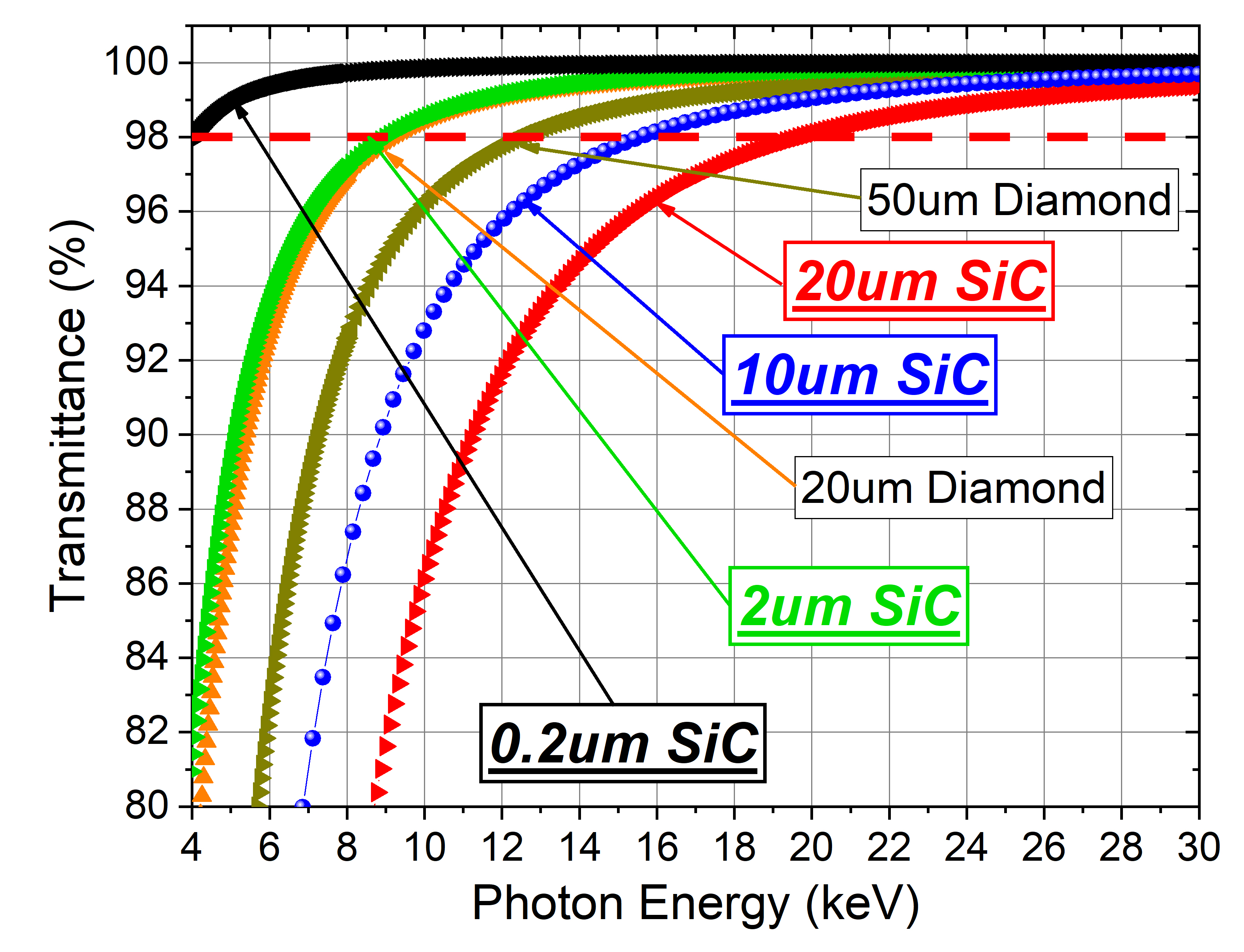

Fig.1 Transmittance of SiC sensors for different thicknesses. Also diamond commercial XBPM are included for comparison

|

|

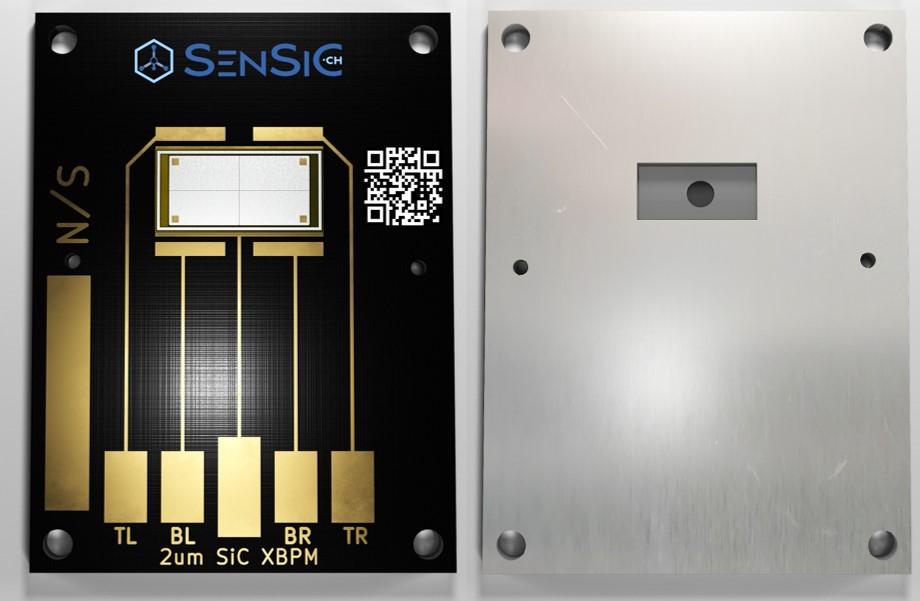

Fig.2 Left) SiC device with gen1 layout assembled on a 4x3cm2 PCB. Electrical connections for the 2x2 sensors array can be seen from front view whereas the 9x3mm2 free-standing thin membrane can be seen from back view. Right) SiC device with gen2 layout assembled on a 4x3cm2 PCB. Electrical connections for the 2x2 sensors array can be seen from front view whereas the 2mm2 free-standing thin circular membrane can be seen from back view.

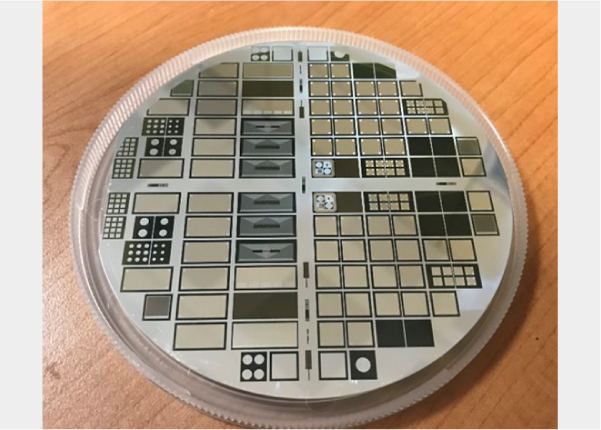

Fig.3 20μm SiC wafer showing all different devices: intensity, position and profile monitors with different geometries

Fig.3 20μm SiC wafer showing all different devices: intensity, position and profile monitors with different geometries

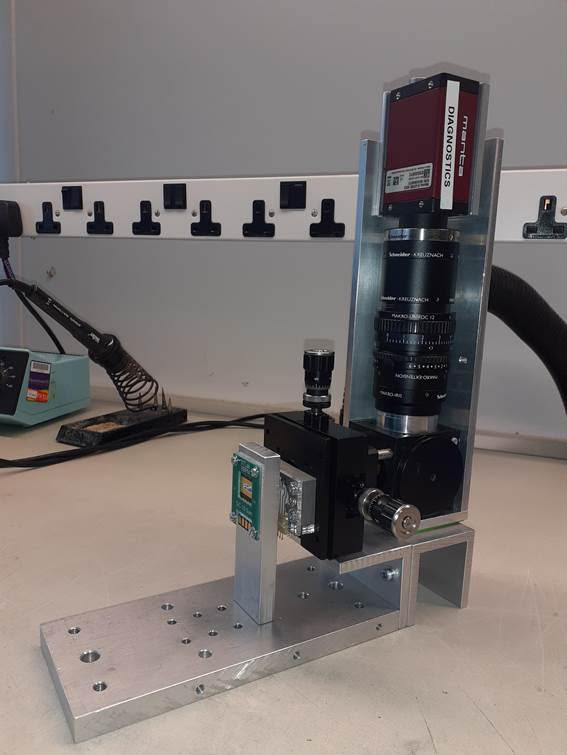

Fig.4 Measuring system used at Diamond ltd to compare 1-1 single crystal diamond and SiC XBPM (presented at IBIC2021) conference, published here)